Ironton Portland Cement Company

IR Jan. 22, 1891 – A New Industry. – The Register has several times called attention to the fact that this locality possesses the most favorable resources for the manufacture of Portland or hydraulic cement. We have every ingredient in our hills and our furnaces increase the facilities. The demand for cement grows yearly, and the business is sure to be good. We copy from the Iron World an article on the subject: [do not have end]

In 1901, Mr. Franklin C. Brownstead became the engineer and electrician with the Ironton Portland Cement. His father, Ernest Brownstead was born in Hanover, Germany in 1821, and came to America at the age of eleven, and died in 1898. His wife, Catherine Mook, was also born in Germany in 1833 and died in 1880. SOURCE: A Standard History of the Hanging Rock Iron Region of Ohio, page 621

In 1901, Mr. Franklin C. Brownstead became the engineer and electrician with the Ironton Portland Cement. His father, Ernest Brownstead was born in Hanover, Germany in 1821, and came to America at the age of eleven, and died in 1898. His wife, Catherine Mook, was also born in Germany in 1833 and died in 1880. SOURCE: A Standard History of the Hanging Rock Iron Region of Ohio, page 621

IR Dec. 11, 1902 – Will Increase Capital. – It is reported that the Ironton Portland Cement Company will shortly take action looking to increase the capital stock to $200,000 and will erect fifty houses and make other improvements to its property. The present stockholders, it is said, will be given the preference in the issuance of new stock and it will be taken largely by them. If the pans of the company are carried out, it will make quite a small town in the vicinity of the plant, many houses having already been erected in the Walburn addition to Coal Grove, adjacent to the industry.

Minneapolis Journal, 24 April 1903 – Stike on at Ironton – Ironton, Ohio, April 24 – Because the Ironton Portland Cement Company refused to give to Ben Garvey his old position as an oiler, the entire force of the plant and of the mines numbering several hundred went out, closing every department of industry.

Columbus Dispatch, 23 Nov. 1907 – Big Ironton Cement Works Changes Hands – Ironton, Ohio, Nov. 23 – Interests represented by D. Linn Gooch of Covington, Ky., Justus Collins, of Charleston, WV., and J. E. Felbig, of Detroit, last night practically closed a deal for the purchase of the plant of the Ironton Portland Cement Company with a daily capacity of twelve hundred barrels. While papers have not been passed parties to the deal admit terms are practically agreed upon.

Big Sandy News, 28 Aug. 1908 – Building Material – The undersigned are selling United States Gypsum Plaster, Ironton Portland Cement, and other articles for builders and contractors, lower than has ever been known in this section of the country.

Ask for prices and be surprised when you received them.

The Z. Meek Co., Catlettsburg, Ky

Cincinnati Post, 9 Oct. 1908 – Ironton, Ohio – Fire destroyed packing house and portion of the warehouse of Ironton Portland Cement Company, together with Norfolk & Western box cars.

Daily Public Ledger, Maysville, Ky., 17 July 1912, page 5 – Big Gas Gusher at Ironton – A wonderfully strong flow of natural gas was struck by the men boring the well on the land of the Ironton Portland Company a few days ago. The gas was detected at a depth of 1,750 feet, in what is known as the Ragland sand, and the flow is very strong.

Portsmouth Times, 6 Aug. 1912, page 11 – Ironton Visitor – James Paul, of the Ironton Portland Cement Co., was a business visitor in Portsmouth, Ohio, Monday afternoon.

Portsmouth Times, 6 Nov. 1912, page 4 – Ironton is waking up – Ironton, Ohio, Nov. 6 – The Ironton Portland Cement Company, which has been contributing not a little to the prosperity of this section with their gas operations, in addition to the steady operation of the cement plant, has awarded the contract to M. F. Stark, of Greenburg, Pa., for the installation of the two big limestone shafts on the company’s property which will tap immense beds of high-grade limestone.

The sinking of these two shafts will be in the nature of a new industry for Ironton for a period of probably six months, as it will require about that length of time to complete the work. The size of the undertaking may be judged from the fact that it will cost between $50,000 and $75,000, and that some sixty or seventy men working in three shifts will be employed during that time.

It is the intention of the contractor to enter upon the work immediately and the necessary machinery and equipment for the work will be shipped here at once. Owing to the great scarcity of common labor in this vicinity at the present time, on account of the resumption at the furnaces, it is likely that the contractor will have to bring in the greater part of his labor with him.

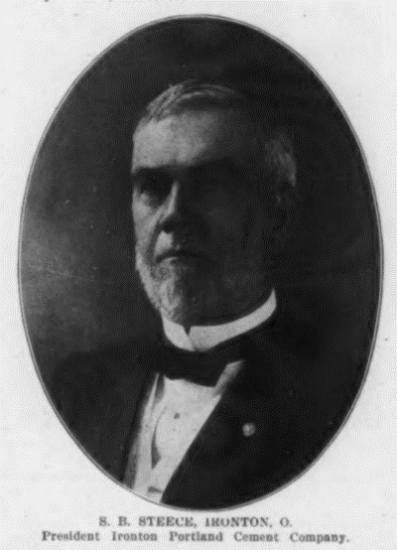

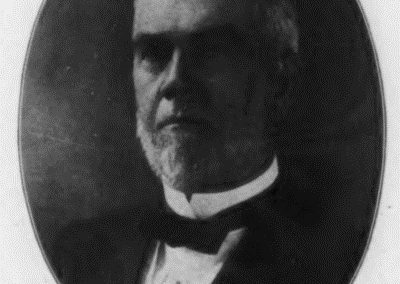

1914 – picture – S. B. Steece, President. Ironton cement meets the test and is used by the Government to build the Ohio River Lock and Dams, and Bridges. [there were two cement plants in Ironton in 1914]

Portsmouth Daily News 15 Sept. 1915, page 16 – Visitors to the Apple Show at Ironton should not fail to visit the display booth of the Ironton Portland Cement Company and see what is possible to do with cement, the ideal building material.

Neither should they fail to see the Moving Picture thrown on a screen near the Ironton Portland Cement Company’s booth. This picture is entitled, “A Concrete Romance,” and is very entertaining, as well as instructive, a pretty story being interwoven with the rehabilitating of an old abandoned farm by the liberal use of concrete in the form of modern concrete, residence, barns, stiles, roads, and in fact everything to make living conditions as near ideal as possible as far as comfort, freedom from worry on account of fire and repairs to the property are concerned. Everybody seeing these displays will be bound to secure a profitable suggestion.

The Ironton Portland Cement Company’s booth is located on Third Street, between Center and Park Avenue and the screen for the Moving Picture is nearby.

Portsmouth Daily Times – 27 March 1917 – Ralph Scott, who travels for the Ironton Portland Cement Company, was a business visitor here from Ironton Tuesday.

SWR May 25, 1917 – Purchases Valuable Land. – Dr.J. W. Lowry Wed. closed a deal and signed the contracts for the purchase of the valuable coal lands formerly owned by Charles Reidel. The tract which is one of the very best in all this section of the country is located just adjacent to the Ironton Portland Cement Company’s plant and it runs clear up to the city. Of easy access, near the railroads, and coal impractical inexhaustible quantities and of high quality render this particular tract very desirable. It embraces 150 acres. Dr. Lowry will develop the land to its fullest capacity in the near future and it is likely he will have associates in the venture. The present demand for coal and its attractive price seems to make this an exceptionally important real estate deal.

Columbus Dispatch, 2 March 1921, page 2 – Indicted Cement Men Notified of Action – More than 100 men and firms are formally charged with restraining trade. New York, March 2 – Arraignment of 74 cement corporations and 42 individuals, members of an alleged “cement trust,” indicted yesterday by a Federal Grand Jury here on a charge of violation of the Sherman anti-trust law, will be made at a date to be decided in the conference by defendants counsel and special prosecutors, it was announced today. Notification of the Grand Jury action was sent to the indicted corporations and individuals. The indictment was the result of an exhaustive secret investigation.

Two counts were in the indictment – one alleging restraint of trade and the other monopolies and attempts to monopolize. Among the names on the list were the following Ohio corporations: The Ironton Portland Cement Company of Ironton, Ohio…

Other corporations named are: The Alpha Portland Cement Company, the Atlas Portland Cement Company…

Columbus Dispatch, 1 Jan. 1930 – Petition Dismissed – The case of Albert C. Steece of Ironton, Ohio, who asked for the recovery of $12,389.54, plus interest from 26 Jan. 1926 for the sale of stock in the Ironton Portland Cement Company was dismissed.

Columbus Dispatch, 1 Jan. 1930 – Petition Dismissed – The case of Albert C. Steece of Ironton, Ohio, who asked for the recovery of $12,389.54, plus interest from 26 Jan. 1926 for the sale of stock in the Ironton Portland Cement Company was dismissed.

Pioneer History of Meigs County, Ohio, page 86 – The Maxville Limestone has excellent purity and uniform quality. Because of its excellent chemical qualities, it has been used for the manufacture of Portland Cement. And it has also been quarried for railroad ballast and for architectural use, the latter because it is sufficiently compact to take a good polish and is of attractive color. It should also be suitable for use as a blast and steel furnace flux, for glass manufacture, chemical industries, manufacture of calcium carbide, water treatment, and as rock dust for coal mines.

Since there are no records available on the quality of this formation in the area under discussion, a brief description of the deposit near Ironton, Ohio, will be given. The Ironton Portland Cement Company sank shafts 510 feet in depth to the Maxville formation which has a thickness of 55 feet in the Ironton region.

The entire 55 feet is very free from siliceous material and is exceptionally low in magnesia and iron oxide deposit is easily mined since it is inside up of thick layers of limestone separated by thin layers of calcareous shales. In addition, the limestone layers are broken vertically every few inches by irregular bedding planes which allow the limestone to be broken down into very small fragments.

A Standard History of the Hanging Rock Iron Region of Ohio, pages 271-273

Great Cement Deposits

All evidence tends to show and proves that this limestone is a marine formation and it is undoubtedly the same limestones as are exposed at Limeville, some sixteen miles below Ironton, in Greenup County. At Carter Caves on Tiger Creek in Carter County, Kentucky, it is what is known as the Chester lime of Illinois and at St. Louis, Missouri, and is also the well-known Greenbrier in the state of Maryland.

Of late years, gas and oil wells drilled in this county in the vicinity of Ironton, have disclosed the fact that the Maxcille limestone near the Ironton Portland Cement Company’s plant exists at a depth of four hundred and thirty-five feet below the surface and that it is practically a single solid deposit of lime ninety-seven feet in thickness.

In Kentucky about one and one-half miles southwest of this cement plant, the vein is apparently split, the upper vein being fifty, and the lower one sixty feet thick and are separated by some sixty feet of sand and white clays. I am inclined to think the lower vein is the true one, as it is only seventeen feet higher than the Ironton Portland Cement Company’s vein. In a core hole one-half mile north of the Ironton Portland cements Company’s plant it is seventy feet in thickness and in the new gas well, one mile east – now being drilled by the Hecla Company – the lime was found to be forty-five feet in thickness. Near Olive Furnace and at the Harper Shaft, some eighteen miles north of Ironton, it is forty-two and forty-three feet thick and the average thickness of this lime in some twenty holes drilled in Southern Ohio averaged more than forty feet.

In Kentucky about one and one-half miles southwest of this cement plant, the vein is apparently split, the upper vein being fifty, and the lower one sixty feet thick and are separated by some sixty feet of sand and white clays. I am inclined to think the lower vein is the true one, as it is only seventeen feet higher than the Ironton Portland Cement Company’s vein. In a core hole one-half mile north of the Ironton Portland cements Company’s plant it is seventy feet in thickness and in the new gas well, one mile east – now being drilled by the Hecla Company – the lime was found to be forty-five feet in thickness. Near Olive Furnace and at the Harper Shaft, some eighteen miles north of Ironton, it is forty-two and forty-three feet thick and the average thickness of this lime in some twenty holes drilled in Southern Ohio averaged more than forty feet.

At Carter Caves, Kentucky, it is probably ninety feet thick, showing what a massive limestone it is wherever it remains undisturbed, as it apparently has been at Ironton.

This limestone has been used in the past for a number of purposes, among which were road building – flux for smelting iron – was burned for lime in many places, and was also found to be an excellent fertilizer. This limestone has also been used for buildings. The Courthouse at Zanesville was constructed of this stone. When polished it resembles marble.

To produce cement the limestone used should not contain more than four and five-tenths percent magnesium carbonate and the less the better. This greatly restricts the possible cement area of the state. Almost all of the limestones in the western half of the state are too high in magnesia. Orton and Peppel say “Limestone or mixture of limestone and shale within the following limits of composition, will be found to be close to the composition desired in a Portland Cement mixture…”

The demand for light-cored cement is growing. For that reason, as well as for the reason that they could produce a better and cheaper cement caused the Ironton Portland Cement Company within the last year to sink two shafts to a depth of 500 feet into the center of this great vein of Maxwell limestone, and from which they are now supplying their plant from a mine whose entries, rooms and galleries are something more than twenty feet in height, with a lime of the wonderful purity sown in the analysis above…

The finding and development of this lime are unquestionable of vital interest to Ironton and Lawrence County – for the day is coming fast when it will be drained to supply the furnaces and steel mills in this Hanging Rock Iron Region.

A large amount of lime that they are now compelled to secure from other parts of this and other states and further the Portland Cement made from this lime has more than fulfilled the hopes and expectations of that gentleman who had the money and nerve to undertake and actually succeed in its development – for, before its accomplishment, the result was more than doubtful, but the final results are proof beyond all doubt of an almost inexhaustible supply of materials int his county to produce cement of better quality than heretofore was being made, much stronger and of a whiteness approaching marble, and at a cost that will stimulate its production in this county – while in all probability, as developments continue, a heavy demand will be made for this lime by all the furnaces and mills of Ironton, Jackson, Wellston, Ashland, Portsmouth and elsewhere, enough is now known to safely predict that Maxwell limestone will shortly become one of the most valuable assets of Lawrence County.

The data and facts contained in this paper are taken from the geological reports of Ohio and particularly Fourth Series, Reports of Professors Newberry, Andres, Orton, and Bownocker, and from observations of A. C. Steece, myself, and others.

Rock Products 1 Jan. 1908, Vol. 7, issue 7, pages 38-39

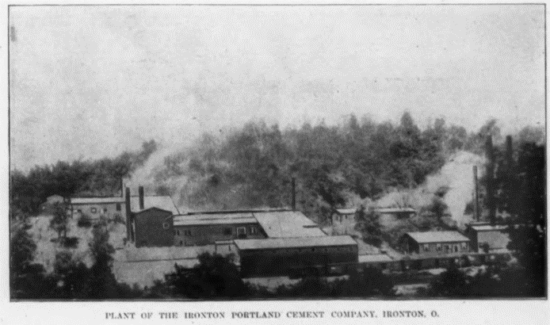

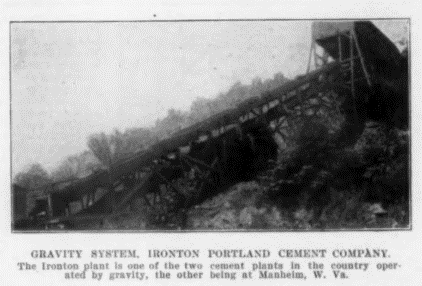

The Plant and Product of the Ironton Portland Cement Company at Ironton, Ohio – Jan. 18 – Erected on the side of a sloping hill, a short distance to the east of this city, is the plant of the Ironton Portland Cement Company, with one exception the only cement plant in the United States constructed on the gravity plan. While the power of gravitation is not depended upon entirely, it is quite an important factor in the handling of raw products from the time they are taken from the earth until the finished product is sacked for shipment.

Besides being erected on a foundation that reaches from the base halfway to the summit of what many communities would consider a mountain, the Ironton plant is peculiar in that its products all come directly from the mines to the mill under operations controlled by the same power that grinds the shale and lime and coal. They enter the upper end of the mill in their native state and come out at the bottom as finished cement.

…Ironton is especially loyal to this particular home industry, and it has probably more cement block houses, industrial plants, retaining walls, and sidewalks and curbs than any city of its population in the Middle West.

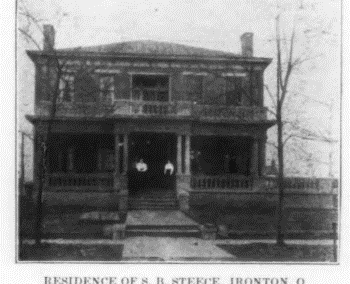

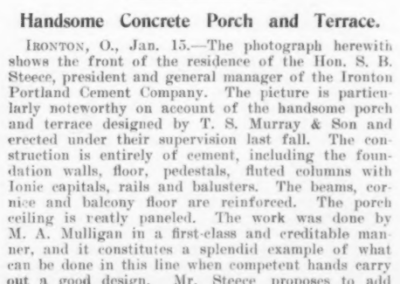

President Steece himself is a true apostle of cement, his own home, which is illustrated on another page, showing a fine example of a porch and terrace of concrete construction.

- IR Feb. 17, 1870 – New Buildings. – Mr. S. B. Steece will erect, this Spring, two fine two-story brick business houses, on his lots immediately above the corner of Second and Centre-sts. The houses will be each 21 x 70 feet, put up with stone fronts, and sundry little attractions. The houses are to be finished by the middle of next May. David McLaughlin has the contract.

- IR July 7, 1870 – Mr. James Haskell, of Ashland, has rented a storeroom in Steece’s new block and will open a store there.

- IR Feb. 2, 1871 – New Buildings. – S. B. Steece intends to duplicate his brick block, in the Spring. And immediately above, Dempsey, McQuigg & Dempsey will erect a large business house.

- IR Apr. 3, 1871 – C. Alderman proposes to build a nice brick business house on his lot just back of Bartram & Peter’s Drug Store.

- IR Dec. 21, 1871 – Important Sale. – S. B. Steece has sold to Bartram and Peters, the business house lot on the corner of Second and Centre-sts, where Boll’s Saddlery shop now is. This is the most valuable lot for a business house now left in Ironton. Messrs. Bartram and Peters intend to put up a fine store, for their Drug business, in the spring.

- IR Sept. 2, 1880 – Dr. Dawson, a prominent Cincinnati physician, and his wife were here on a visit, last week, stopping at their cousins, Mrs. S. B. Steece’s.

- IR Sept. 15, 1887 – Steece’s new block will be built next Spring.

- 1914 – picture – A glimpse of the porch of S. B. Steece’s handsome home on North Fifth Street.

0 Comments