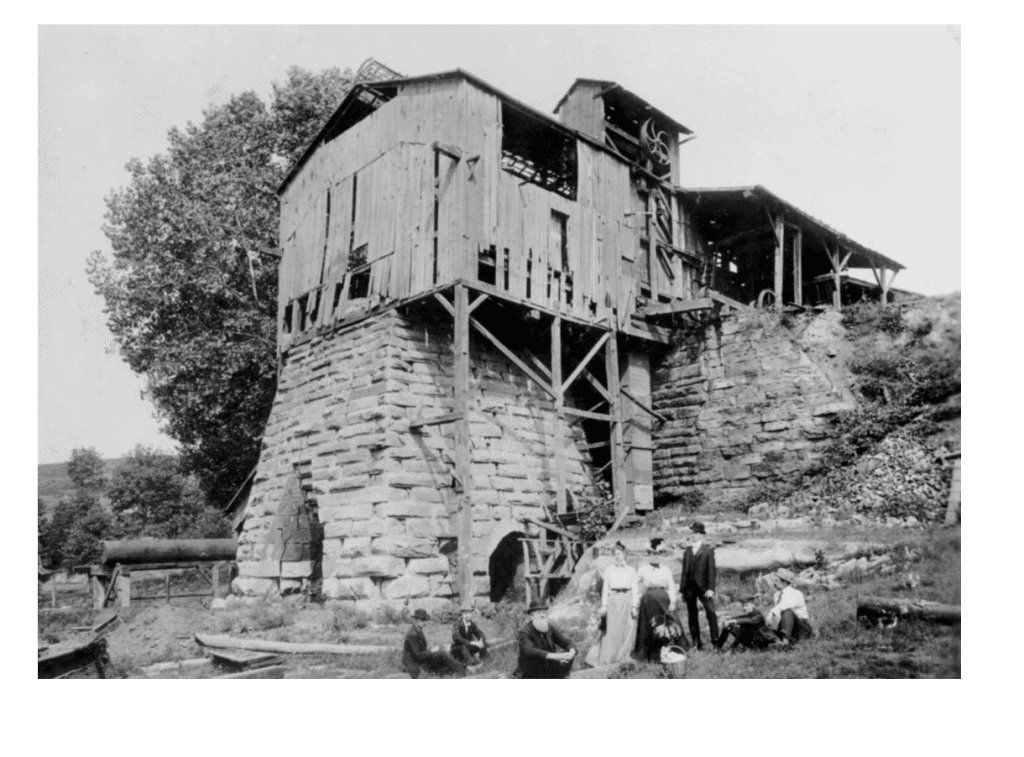

Pine Grove Furnace, Lawrence County, Ohio

Built: 1828 by ROBERT HAMILTON, A. ELLISON

Closed: May 10, 1895

Torn Down: April 1899.

Researched by Sharon M. Kouns

Pine Grove Furnace was built in 1828 by Andrew Ellison, Sr., Andrew Ellison, Jr., and Robert Hamilton, who, from a tour through the country in the fall of 1827, became convinced that there was ore enough to justify them in building and therefore selected the site and made entries of land. Whether their investments proved profitable might be told hereafter.

Photo courtesy Ohio Memory Project

We will not here state the difficulties of building a furnace at that time and of getting things from a distance. The Furnace was fired on Jan. 1, 1829, and blew on January 13, 1829. Up to 1832, the business was carried on under the style of “Ellison & Hamilton.” The firm changed to “Ellison, Hamilton & Co.” bout the year 1834, Andrew Ellison, Jr. died, and the property was rented to Robert Hamilton at an annual rent of seven thousand five hundred dollars. Until 1834, most of the iron was made into stoves and castings. Sundays, however, were devoted to making pig iron exclusively. The Furnace made three or four tons of iron in 24 hours and sometimes thirty tons per week for seven days.

Ironton Register, July 30, 1885 – (Country Notes) – Pine Grove is running steadily on, making an average of 18 tons a day of an excellent grade of iron. She is running a hot blast. The company gets about fifteen hundred bushels of charcoal a day from the Scioto Valley railroad. The coal is brought mostly from Pike county. The car in which they ship holds fifteen hundred bushels. The coal is unloaded from this car into others at Newcastle, holding about two hundred bushels, and is hauled over to the Furnace on the tram road with mules. It is forked out of the large car into the small ones.

C. Ketterer is still in the store at Pine Grove, and Miss McIntosh, daughter of the manager, keeps the books in the office. This is the only instance of a lady clerk at a furnace in this iron region. Miss McIntosh only does the clerical work, omitting many of the duties usually developing upon the clerk at a furnace.

Instead of letting the cinder run at will, as used to be the way at charcoal furnaces, Pine Grove is flushed now as is done with a coke or stone coal furnace. They say it requires much less skill to keep a furnace when the cinder is tapped than when it is allowed to run out all the time. The cinder is let out every hour, except after casting, when it is held for two hours.

Mr. H. Placker is the foundryman at Pine Grove, and how the Furnace rolls out the metal proves that he knows what he is doing.

Father Rauck is having a neat, new fence placed in front of his dwelling at the crossing. H. A. Hosey, the deaf-mute, is doing the job.

Ironton Register, January 14, 1886 – Pine Grove started on her new hearth on Tuesday of last week.

Robert Hamilton was the manager at Pine Grove Furnace in 1830. Robert Hamilton was married to Nancy Ellison. Their niece, Elizabeth C. Clark, married John Campbell.

Ironton Register, August 25, 1904 – Pine Grove furnace was built in 1838 (sic 1828) by Andrew Ellison, Sr., Andrew Ellison, Jr., and Robert Hamilton, who, from a tour through the country in the fall of 1827, became convinced (NEED END OF ARTICLE)

John Peters learned the moulder’s trade at Pine Grove Furnace at nineteen (1833) for two years, then went to Mount Vernon Furnace.

Semi-Weekly Irontonian, November 8, 1907 – Andrew Ellison first came to Pine Grove Furnace, built in 1828 by Andrew Ellison, who had capital, and Robt. Hamilton, who had some capital. Robert Hamilton, from Penn., clerked at Brush Creek Furnace, Adams Co., Ohio. He opened the Newcastle Mines, built the Hanging Rock Railroad, lived at Pine Grove for 24 years, moved to Hanging Rock in 1853, and died there. His first wife was an aunt of Mrs. John Campbell, which marriage was the beginning of his success and fortune.

LAST OF PINE GROVE FURNACE – Ironton Register, April 6, 1899

Pine Grove Furnace, another of the historic and profitable properties in the iron business of this section, is being torn down by its owners, Means, Kyle & Co., and the cast iron about the plant, of which there was a large amount, is being remelted in their modern Hamilton Furnace at Hanging Rock.

Pine Grove was one of the very first furnaces erected in the Hanging Rock iron region and was the last of the earlier furnaces to be abandoned. Only five furnaces in this region antedated Pine Grove. Argillite in Greenup Co., Ky., was built in 1818; Steam and Pactolas of Greenup in 1824. Union in 1826, Franklin in 1827 in Scioto county, and Pine Grove in Lawrence in 1828. Scioto Furnace was built the same year, and Amanda, across the river from Ironton, in the year following.

Robert Hamilton and A. Ellison were the builders, and the Furnace continued in blast almost yearly until it finally closed on May 10, 1895. Now, two boilers which were used there from 1849 till that time, are converted into smoke stacks and project from the roof of the Eagle Mill, and the materials available to other uses are being removed from the site, which was the scene of activity in iron making for nearly 70 years.

PINE GROVE FURNACE

(For the Register) Ironton Register, Thursday, September 14, 1854

Submitted by Jean Griesan for The Lawrence Register website

As stated in the REGISTER, two or three weeks since, we shall give, as far as we are able, a sketch of each Furnace in this iron region. In this, we hope to receive the hearty co-operation of the different Furnace men. Give us the facts, and no matter the shape they come in – either in the form of a communication; or in a manner that we can put them together in articles of our own.

The first Furnace built on this side of the river in this region was Union; Franklin, the second; Pine Grove Furnace, the third. From deficient information about Union and Franklin, we are obliged to commence with Pine Grove Furnace; this “breaks the ground” and lets others follow.

This Furnace was built during the year 1828 by Andrew Ellison, Sr., Andrew Ellison, Jr., and Robert Hamilton, who, from a tour through the county in the fall of 1827, became convinced that there was ore enough to justify them in building and therefore selected the site and made entries of land. Whether their investment proved profitable might be told before the conclusion of this article; enough will be seen to show that their conclusions were good regarding ore.

How much land they entered I cannot now state, but it doubtless would have been seed sowed on the good ground had they entered ten times as much as they did, as it would have prevented small purchasers from scouring land enough on which to start a whisky shop, either to be bought out at a great advance or to prove as in many instances, an eyesore to a Furnace.

Many incidents I shall omit, such as the famous “rat story,” which others, eyewitnesses, could tell better about if they would. Still, I shall confine myself to what I have seen with my eyes and the figures from the books.

As stated before, Pine Grove was built in the year 1828. I the difficulties of building a Furnace at that time and of getting things from a distance, I will pass over. I found this entry about the journal kept at that time: “Fired Pine Grove Furnace January 1, 1829, and blew January 13, 1829.”

Up to the year 1832, the business was carried on under the style of “Ellison & Hamilton,” when by the introduction of another partner (why didn’t our correspondent name the other partner!), the firm was changed to “Ellison Hamilton & Co.”

About 1834, Andrew Ellison, Jr., died, and the property was rented to Robert Hamilton at an annual rent of seven thousand five hundred dollars.

Up to 1834, the Furnace had been carried on under many disadvantages; most of the iron was made into stoves and castings. Sundays, however, were devoted to the making of pig iron exclusively. It would be hard to come at the exact quantity of iron made during these five years, but it was considered a fair business when the Furnace made three or four tons in 24 hours, or, very fair, thirty tons per week of seven days.

Having rented the Furnace at a very high rent, Robert Hamilton stood him in hand to push the business with all possible energy. He made contracts for castings, stoves, and salt kettles and continued this business for several years.

In 1837 a new era dawned on the iron business, the introduction of heated air into the blast. Some three or four Furnace men met at Vesuvius Furnace carried on by Hurt, Gould & Co., and there agreed that they would test the hot blast principle – to employ a man to put up a hot blast at Vesuvius.

If it proved to be a satisfactory experiment, Hurd, Gould & Co. were to pay all the expenses, but if a failure, the expense was to be divided among the agreeing parties. Wm. Firmstone put up the hot blast; it proved satisfactory to all parties. This was the introduction of a hot blast into Lawrence county.

Mr. Hamilton immediately had a set of pipes, very different from those now in use, made and put up at Pine Grove; however, it was contended by those opposed to the principle that the iron was weakened by the hot blast and made unfit for casting purposes, but the result proved that it was the very kind of iron that foundries wanted.

Pine Grove persevered in the hot blast through difficulties, Mr. Hamilton still renting the entire property until 1840 — making six years in all that he had rented the portion of the Furnace belonging to his partners. During the last year, under his rent, he abandoned the casting business and made only pig iron.

In 1840, Robert Hamilton became the sole owner of Pine Grove Furnace, and from the commencement of the next blast, an accurate account has been kept of all the sales, of all the iron made, &c., some of which figures will presently appear. Mr. Hamilton associated with him as partners John Ellison, James A. Richey, and Joseph S. Peebles, under the style of “Hamilton & Co.” This partnership continued for three years, to January 1844. During that time, the Furnace made 4,500 tons of pig iron.

Mr. Hamilton, now having the Furnace entirely under his own control, determined to try an experiment that he had long desired to try as there was now no person but himself to blame or to injure in case it should not succeed, the stopping of the Furnace on the Sabbath. That it would not succeed was predicted to him by many of those he considered his friends, yet he was resolved to try it although it might cost him the loss of many years gain which the Furnace had hitherto made him. He was disposed to give it a fair trial; he took down the old stack (which might have lasted many years notwithstanding its props) and built a new stack that is now in use and shows for itself the work of a master workman.

Several thousand dollars were expended on improvements of the most permanent character; the boilers were then put on the top of the stack, and the heat was first conveyed from the trundle head under the boilers to the hot blast. Also, an improvement was adopted and set into operation profitably by Mr. Towers, doing away with the old-fashioned siphons and adopting in their stead circular rings made from a pattern furnished by Peebles, Wood & Co., Hanging Rock. These improvements consumed the greater part of 1844 and the stoppage of Pine Grove Furnace on the Sabbath from the 20th day of December that year.

No one but Mr. Hamilton and those employed by him can be aware of the troubles that commenced about that time. For instance, the pump refused to throw water, and the cause was not discovered for several days. Many there were who were not slow to invent a cause, which I will not repeat. It was a bad time to commence an enterprise of the kind in the winter; it is better to start a Furnace in warm weather, but the edict was that from that time forward, Pine Grove was to be carried on under the Sabbath-keeping principle.

How it has prospered under this principle will be shown by the tables accompanying this sketch, taken from a book set apart for that purpose, subject to the inspection of all who are curious to know the number of tons of iron made by Pine Grove Furnace during the day, week, month, or year.

From Dec. 20, 1844, to Jan. 6, 1847, Mr. Hamilton carried on the Furnace on his own individual account, long enough to satisfy him and all those favorable to the project that there was no reason for blowing a Furnace on the Sabbath day. During that time, many hard things were said of Mr. Hamilton and his folly, but he lives to see his Sabbath-keeping system, at present adopted by many Furnaces, and hopes to live to see the day not very far distant when the puff of a Furnace shall not be heard on the Sabbath.

About the 1st of Jan., 1847, Mr. Hamilton associated with him John G. Peebles, John F. Steele, and Samuel B. Hemstead, the first as Manager, the second as Clerk, and the last as River Agent, at Hanging Rock, under the style of “R. Hamilton & Co.” This firm continued until Oct. 25, 1850, when Mr. Steele died very suddenly than whom a more gentlemanly young man could not be found.

All who had business with him will testify to his fair dealing and honesty. Passing the graveyard at Pine Grove will be seen a beautiful marble monument, enclosed by an iron fence, bearing this inscription: “John F. Steele, born March 1, 1822, died Oct. 25, 1850;” also a neat little slab bearing the inscription “Little Mattie,” buried one day previous to the death of the father, who in common health attended the burial and little did he think that in so short a time was his body to be placed beside that of his little daughter.

During the time that the Furnace was carried on by R. Hamilton & Co., an accident occurred, which, had it happened two or three years before (like many smaller accidents), would have been attributed to stopping the Furnace on the Sabbath. I refer to May 9, 1850, when an accident occurred that resulted in the instant death of John Willis. It was only a few hours after the blast had been put on, and many persons had collected in the pothouse to see the Furnace let out its first (or second) iron bed.

The iron was just let out when an explosion occurred with an awful noise, and scattered timber flew about in all directions. What a moment of suspense. Fathers, mothers, brothers, and sisters are hastening to the scene. As it happened, it was a remarkable preservation of those about the Furnace, and only Mr. Willis lost his life. A contribution was taken up for the support of the widow and the children, and all who lived on the ground were glad to contribute to the support of those who had been deprived of a husband and parent who had sustained an excellent reputation for honesty and industry.

The damage by this explosion amounted to several thousand dollars. Still, all the fixtures were put up on a more permanent plan, all repairs were made, and the Furnace was again in blast in 20 or 21 days, and would have been several days sooner but for the delay in procuring new boilers. Since that time, the Furnace has been prosperous.

After the death of Mr. Steele, as stated in Oct. 1850, the other partners purchased his interest, and the firm became “Hamilton, Peebles & Co.” The Furnace worked well, and many letters were received from persons engaged in the same business, requesting an account of how the Furnace worked, the quantity of iron made, and many like questions.

And here let me say that this sketch is made without the knowledge or comment of Mr. Hamilton or any of the above-named parties, Hamilton, Peebles & Co. Consequently, many things will probably be omitted that might be of great interest; and those acquainted know them to be men not in the habit of “gassing” but prefer doing business in a manner for which the world is not much the wiser. Anything pertaining thereto has to be ascertained as best can be.

Consequently, their private business is a matter best known to themselves. —- The writer of this sketch has respectfully asked them for a statement from their own hand, but they positively declined to publish anything, remarking that it might be considered “bragging.” But the following account, which is correctly copied from the books, I can see no harm in publishing. Previous to 1841, the amount of iron made by the Furnace cannot be correctly ascertained, as it was mostly made into castings.

From this statement, it will be seen that from 1841 to 1854, the Furnace made almost 23,712 tons of Pig Iron. Let us suppose that from Jan. 1829 to Jan. 1841, a period of 12 years, during which, as before said, no accurate account was kept, the Furnace made 600 tons per year, which would amount to 7,200 tons. Add to the above, and you have 30,712 tons of Pig Iron made by Pine Grove.

Now it is commonly supposed that 200 bushels of charcoal are required to make a ton of Pig Iron. (Some Furnaces require more and some less.) Here then, is the enormous amount of 6,112 – 1000 bushels of charcoal used. Also, 2 ½ tons of burnt ore to the ton of Pig Iron gives nearly 80,000 tons of ore used and limestone in proportion. And I may add that more than 19,000 tons of this metal have been made since the Furnace commenced stopping on the Sabbath.

On the 1st of March 1854, Mr. Hamilton sold one half of the Furnace to John G. Peebles, Joseph S. Peebles, and Samuel Coles, now carrying on the Furnace under the style of “Hamilton, Peebles & Coles,” and no part of their business is taken into the above account.

The buildings of Pine Grove will probably compare favorably with those of any other Furnace and number fifty, or perhaps more. There is a school house or meeting house, and preaching regularly on every Sabbath; also, for the past three or four years, the Furnace has had the constant benefit of an excellent school teacher, who gives universal satisfaction, so much so that people send to the school from a distance. Also, I am told there is a prosperous though small, Sabbath School in operation.

I may remark that there now belongs to the Furnace somewhere in the neighborhood of 10,000 acres of land, the boundaries of which ran off by the late County Surveyor, and that the iron made by Pine Grove has ever stood “A No. 1” in any market wherever it has been sold.

But this communication is already too long; emissions in the account may be supplied at another time. Nothing has been stated above but facts, which others in the county, who have been connected with the Furnace, could have stated better, but as they might not be disposed to undertake it, you have my account. I have nothing which I can state regarding the financial affairs of the Furnace, but from all I can learn, Pine Grove has made as much money as Furnaces in her class generally make, that stop on the Sabbath.

P.S. Since writing the above, a piece of paper has come to my notice, bearing the date 1830, as follows:

| 400 tons of castings at $60 | $24,000 |

| 500 tons of pig iron at $28 | $14,000 |

| 100 tons scrap | $2,500 |

| Total | $40,500 |

This was made out to show what the Furnace had done during the first (or second) blast, and from it may be seen that my estimate of 600 tons of Pig Iron per year made during the first twelve years of the existence of the Furnace is probably full low.

0 Comments