Oak Ridge Furnace, Lawrence County, Ohio, Was Built in 1856

By: PROF. W. W. MATHER, GEN. O. M. MITCHELL

Charcoal

Researched by Sharon M. Kouns

Ironton Register, February 19, 1857 – Oak Ridge Furnace – which will probably commence its first blast in May next, is the 14th furnace built in Lawrence county.

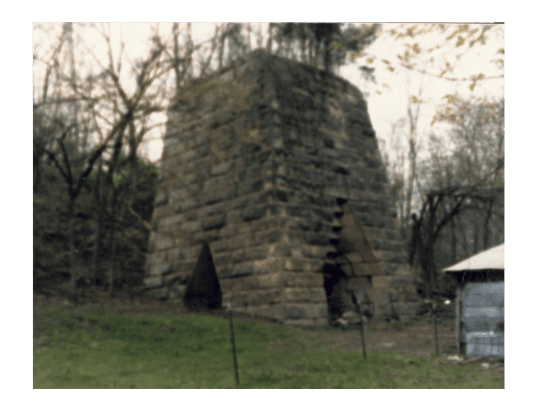

This photograph shows the abandoned Oak Ridge charcoal furnace. The furnace, located in Lawrence County, Ohio, was built in 1856 by William Williams Mather and O.M. Mitchell. Mather was the first state geologist of Ohio.

Mather and Mitchell failed to make a profit and soon sold the furnace. The Hecla Furnace later acquired it. The photograph, which measures 3.5 by 4.5 inches (8.89 by 11.43 cm), was taken by Virgil and Marguerite Ramsey.

The furnace was one of many in the Hanging Rock Iron Region, an area rich in red hematite iron ore and the other materials needed to make iron, limestone, and charcoal.

The region includes the Ohio counties of Lawrence, Jackson, Scioto, and Vinton, northeastern Kentucky, and the western part of West Virginia. Charcoal furnaces were constructed of two layers, an outer one of sandstone blocks and an inner layer of fire brick or sandstone.

To make a ton of iron, approximately 200 bushels of charcoal, 5,000 pounds of iron ore, and 300 pounds of limestone were heated until molten. Impurities floated to the top, forming a waste product called slag. Iron was collected in the bottom of the furnace and poured into troughs to cool. Because the troughs resembled a sow suckling her pigs, the product was known as pig iron.

Ironton Register, Thursday, February 19, 1857 – MESSRS. STIMSON & PARKER: A few days ago, I made a visit to Oak Ridge Furnace, in the company, with my friend Nathan Booth, an eminent founder from Pennsylvania. On our arrival, we were fortunate to meet Professor Mather, by whom we were very kindly entertained. We proceeded to examine the Furnace stack.

We were pleasantly surprised at its noble and proportionate structure, this complete workmanship on which reflects great credit on the mechanical abilities of the builder, Mr. Allison of Ironton. We pronounce it the best furnace stack we have seen in this region of the country. Nothing seems wanting to its perfect completion, but a hearth and inwall of Ashland firebrick of the Stoll & Rose brand.

From the furnace, we proceeded to visit the “SEVEN FEET VEIN OF COAL,” lying above the top of the furnace, thus rendering its transportation to the same easy and cheap; and, to our entire satisfaction, we found the full seven feet of the clear grit of coal. Besides this, there are five other veins of the same material, varying from 2 to 5 ft. in thickness, all of the excellent quality.

As to the ores, our humble descriptive abilities are utterly inadequate to do them justice. The various veins of limestone ores, with a two fee vein of block ore, all of the excellent quality, bespeak for Oak Ridge a destiny, second, not seven, to the world-famed Dowlele (or Dowlala) Iron Works of South Wales or the Calderbank Iron Works of Scotland, in its ample, and almost inexhaustible natural resources for the manufacture of an unlimited amount of Iron of the best quality.

Should Professor Mather be as successful in the selection of his men, and carrying his works into operation, as he has been in the selection of the location, he will have no cause to regret embarking into the manufacture of Ironton.

Having spent the greater portion of the day examining a portion of the above extensive and very rich mineral property and the evening listening to highly interesting accounts of some of Mr. Mather’s professional explorations, &c., &c., we left the next morning highly pleased with our visit, and fully satisfied of the truth of what I have above stated. JOHN J. VINTON.

Ironton Register, August 13, 1857 – Oak Ridge Furnace commenced its first blast last week, letting out iron for the first time on Saturday forenoon. The character of the metal was such as to give full satisfaction to all parties interested, and good judges not interested say it was better than is usual at the first run. It is a hot blast, charcoal iron, but it is understood that the second blast will be made with stone coal. Oak Ridge is one of the best-built Furnaces in this Iron Region.

Ironton Register, May 13, 1858 – Oak Ridge Furnace was to go into blast on Monday of this week (its second blast) with a first-rate stock on its bank. – We believe an unmistakable authority now settles that there is “a plenty” of good ore – block ore – near the Furnace, easily obtained, and no one ever doubted its abundance of “timber” and its excellent veins of superior stone coal.

The Furnace is thoroughly built, one of the best, and prudently managed – why will it not succeed handsomely? John Thompson, the Founder, a faithful man, got up this stock, and if the Furnace does not do well, it will not be his fault, we feel quite certain. We trust Col. Mather will soon return to Oak Ridge, his other business accomplished, so that he can carry out to success his favorite enterprise.

0 Comments